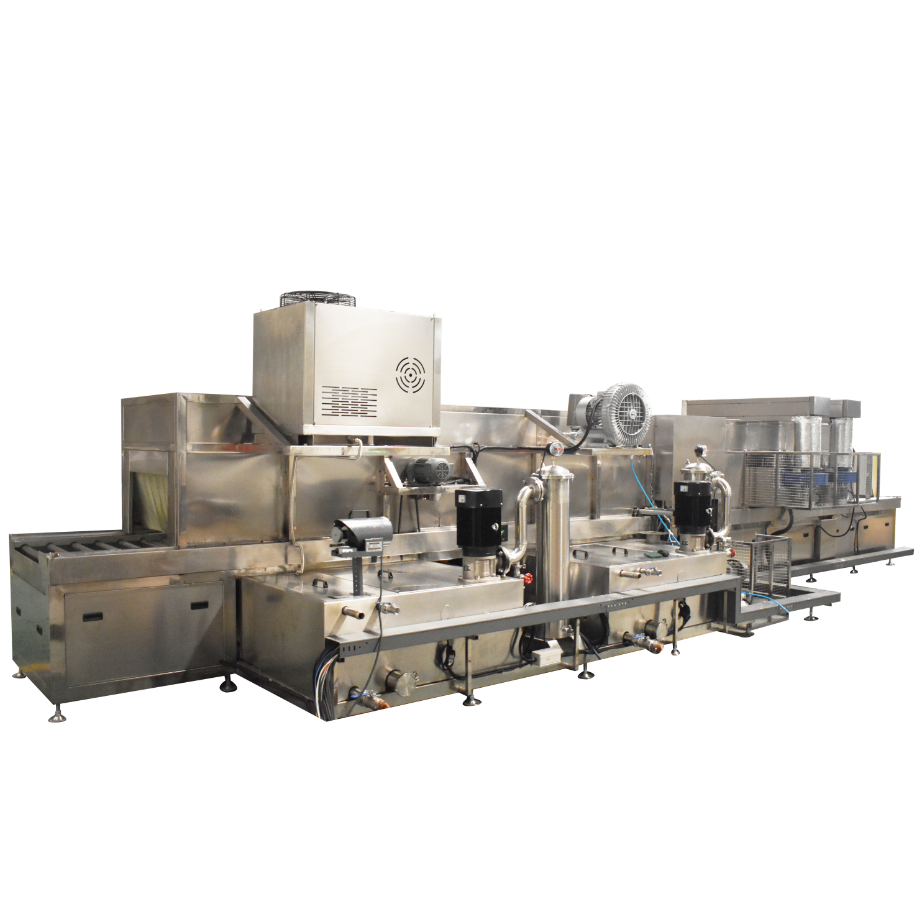

→ (01) Set various parameters for device operation and control the operation and stop of the whole machine through the touch screen on the device.

The workpiece is transported by the automatic roller conveyor line of Party A to the feeding station roller conveyor of the cleaning machine. The workpiece is sent from above, with the front (wheel surface) facing upwards. Protective plates are installed on both sides of the roller conveyor to prevent the workpiece from deviating.

At the loading station, the equipment operating device automatically transports the workpiece to the spray cleaning station for high-pressure spray cleaning. There is a stainless steel spray pipe in the cleaning room, and the nozzle is installed on the top, bottom, and both sides of the spray pipe. The angle of the nozzle can be adjusted to cooperate with the cleaning agent for preliminary cleaning of the workpiece.

After the spray cleaning is completed, the conveying device is driven to the precision spray rinsing station for spray rinsing; There is a stainless steel spray pipe in the rinsing station, and the nozzle is installed on the top, bottom, and both sides of the spray pipe. The angle of the nozzle can be adjusted; It can completely remove residual liquid on the workpiece and improve the cleanliness of the workpiece surface.

After the high-pressure spray rinsing is completed, the conveying device drives the workpiece to the wind cutting and water blowing station; This workstation uses a high-pressure fan, with an air knife installed in the tank. The air nozzle can quickly dry the residual moisture on the surface of the workpiece.

After the wind cutting and water blowing are completed, the equipment operating device automatically moves the workpiece to the hot air drying station, uses an air heater to heat the air, and blows it out by a high-temperature fan to quickly dry the workpiece.

After the hot air drying is completed, the equipment running device automatically moves the workpiece to the cooling station. The cutting station is equipped with a cooling fan, which can cool down the station.

After the cooling is completed, the roller conveyor at the unloading station is connected to the automatic roller conveyor of Party A for material receiving, and the cleaning process is completed.

TEL

TEL

Product

Product

Case

Case

Contact

Contact